Air quality plays a critical role in the performance and reliability of industrial systems. Even microscopic particles can cause excessive wear on equipment, reduce efficiency, and lead to costly breakdowns. While traditional filters can remove dust and dirt, they often miss the more ferrous contaminants that cause the most damage.

Many facilities instead rely on magnetic air filters, which use static electricity to capture and hold airborne debris before it reaches sensitive components. This results in cleaner air, extended equipment life, and measurable cost savings.

Benefits and Features

Magnetic compressed air filters from Delta Industries Inc. deliver benefits that go beyond standard filtration, providing a layered defense system to capture dust, pollen, and debris. This makes them a wise investment for OEMs, maintenance managers, and any operation looking to reduce downtime and extend system life.

The benefits and features of magnetic air filters include:

Targeted particle removal. Magnetic air filters effectively capture a wide range of airborne particulates before they can reach equipment, helping to prevent unexpected failures and minimize repair costs.

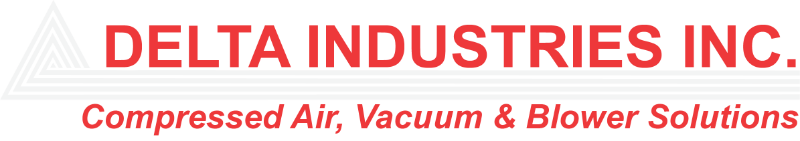

Targeted particle removal. Magnetic air filters effectively capture a wide range of airborne particulates before they can reach equipment, helping to prevent unexpected failures and minimize repair costs. Extended filter media life. Our filters are constructed using washable electrostatic media in a metal frame (typically galvanized steel or aluminum), which means you save on maintenance and long-term replacement costs.

Extended filter media life. Our filters are constructed using washable electrostatic media in a metal frame (typically galvanized steel or aluminum), which means you save on maintenance and long-term replacement costs. Energy efficiency. Cleaner systems run with less resistance and strain. By preventing buildup and blockages, magnetic air filters can improve airflow and reduce overall energy consumption.

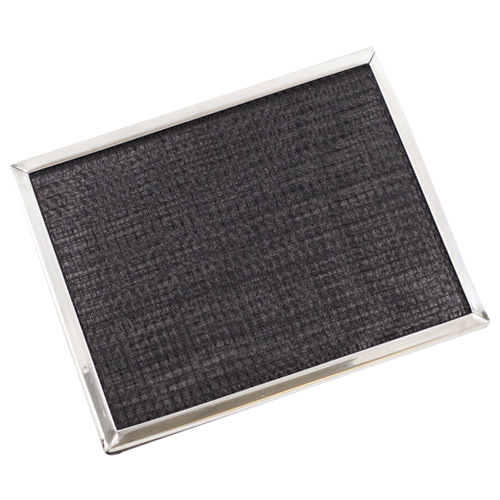

Energy efficiency. Cleaner systems run with less resistance and strain. By preventing buildup and blockages, magnetic air filters can improve airflow and reduce overall energy consumption. Simple to install. Our magnetic compressed air filters are easily affixed to any unit using the magnetic stripping. They can be custom-designed to fit any equipment and size, depending on your needs.

Simple to install. Our magnetic compressed air filters are easily affixed to any unit using the magnetic stripping. They can be custom-designed to fit any equipment and size, depending on your needs. Environmental benefits. Model R filters from Delta Industries Inc. come with a 5-year warranty. Longer filter life and fewer part replacements help reduce waste while saving on material costs.

Environmental benefits. Model R filters from Delta Industries Inc. come with a 5-year warranty. Longer filter life and fewer part replacements help reduce waste while saving on material costs.

| Model | R1 | R2 |

| Average Arrestance Efficiency | 42% | 72% |

| Dust Holding Capacity | 67 gm. | 100 gm. |

| Initial Air Flow Resistance | 0.02″ w.g. | 0.05″ w.g. |

Applications

Airborne contaminants don’t affect every industry in the same way. For instance, a food processing plant faces different challenges than a pharmaceutical manufacturer or an electronics cleanroom. What they all share, however, is the need to protect equipment, maintain quality, and keep operations running efficiently.

Magnetic air filters can be adapted to a wide range of environments, making them reliable solutions for particle control:

- Manufacturing environments. Machining, welding, and fabrication generate dust that can recirculate through air systems. Magnetic filters protect both equipment and employees by removing these contaminants.

- Automotive and aerospace. Both of these industries demand precision and durability. Magnetic filters extend the life of compressors used in assembly and production.

- Electronics production. Airborne particles can disrupt sensitive electronic components. A magnetic air filter adds a layer of protection that supports improved air quality.

- Food and beverage processing. Air quality is closely regulated in these facilities. Magnetic filters ensure that pneumatic lines remain free from contaminants, helping to maintain product safety and compliance.

Delta Industries can supply engineered magnetic air filters tailored to meet the unique requirements of each system, ensuring every industry receives the right level of protection.

Request a Quote

A magnetic air filter provides a proven method for capturing these particles, safeguarding your investment, and ensuring smooth operations. Whether installed in compressed air systems, HVAC units, or specialized manufacturing environments, a magnetic air filter offers a level of protection that standard filters cannot match.

Delta Industries supplies standard and custom magnetic air filters designed for durability, efficiency, and long-term performance. Our experts will help you identify the right solution for your application. Request a quote to get started.